The best gating system was tested to produce 50 parts, with the purpose of further reducing reoxidation combined with the best compromise for filling time, a smooth filling and sand inclusions. The assessment showed a strong correlation between the gating geometry and reoxidation, but there was no clear tendency to solve the sand inclusion defects. This finally resulted in a first Design of Experiments (DoE) with 16 differerent gating designs, with the aim to find a variation suitable to reduce sand inclusions and air entrapment at the same time. However, to keep the task efficient, the number of variables and experiments were decreased with the goal of quickly identifying the most critical tendencies. The gating system was parametrized using 12 geometrical variables, resulting in a possible 4096 combinations. The program has similar functionality to Auto CAD and can easily be. However, the filling time could not exceed 12 seconds to continue to ensure optimal productivity. I am employed in a small business and ARC CAD does a good job in meeting our needs. As the engineers could not clearly identify which of these was the main cause for the observed problems, they decided to further investigate both objectives in the optimization process. Perform validation experiment and compare to the results of a simulation of the experiment: Perform a small-scale experiment to test and validate the model at participating.

#Doe magmasoft code#

This showed that the inclusions were caused by both reoxidation and sand erosion. code in MAGMASOFT: Researchers from the University of Iowa will directly collaborate with MAGMASOFT to implement the model into a commercial casting simulation code. Amstettens staff does not just produce castings for the Heidelberg Group: 50. MAGMAsoft in conjunction with the concept of design of experiments (DOE) to limit the number of simulations required for optimizing a given set of process parameters.

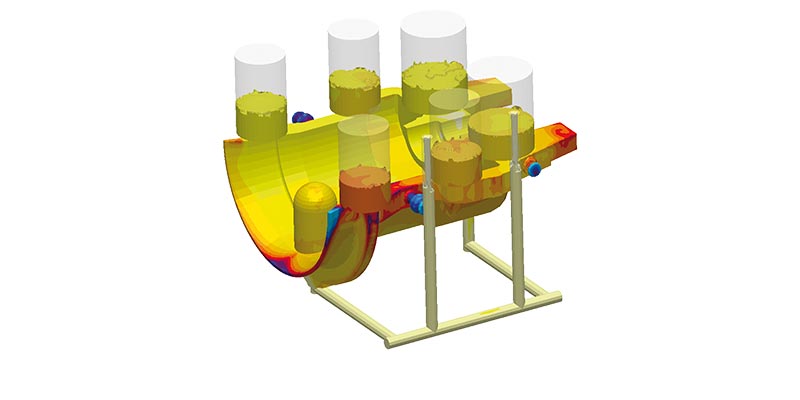

The presentation will illustrate a reference application of HPDC and AM simulation coupling, the advantages of the two manufacturing processes, and the thermomechanical performance of the die-casting insert developed with the new approach.The defect analysis with MAGMASOFT ® started with reproducing the original conditions and environment of the casting process and the gating system. Heidelberg Foundry Amstetten Simulates Casting Processes with MAGMASOFT.

AM process simulation to optimize die-casting tooling | Nicole Nardo, EnginSoft In this presentation, we will present a complete and comprehensive design of the HPDC injection chamber and flux curve to minimize the air entrapped in the chamber. The definition of first phase velocity in HPDC projects with MAGMASOFT | Felipe Cebukin, MAGMA Engenharia do Brasil Ltda

#Doe magmasoft windows#

MAGMASOFT and EnginSoft have been partnering to promote the benefits of process simulation within the manufacturing industry for many years. SiMo Ductile cast iron is a special material designed for high-temperature applications like exhaust manifolds, turbo charger housings used in automotives. Thursday 3 December 2020 Time slots: 2:00 PM CET | 10:00 PM CET | 6:00 AM+1 CET Duration: 01:40:00 MAGMASOFT: The virtualization of casting production

0 kommentar(er)

0 kommentar(er)